8.1 Our environmental performance

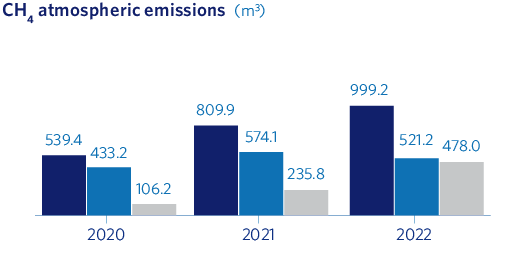

During 2022, in terms of the environment, we have maintained our system of environmental performance indicators, and have perfected the event-based methodology for estimating fugitive methane emissions from the distribution network, separating emissions scope 1 and scope 3, the result of which is taken into account for the corresponding carbon footprint report.

In addition, notification of reports of contaminated soils from the dismantled LPG plants has continued at a good pace, and many of the soil properties and the conclusions of the administrative resolutions related to this process have already been notified.

Moreover, we have continued with all environmental activities related to the maintenance and improvement of our Environmental Management System, which is certified according to standard ISO 14001:2015, and have also carried out the corresponding audits.

8.1.1 Environmental objectives

With respect to the two objectives established for 2022, the follow-up status is as follows:

- Reduce the environmental footprint by 3%

Only 29% of this objective has been met, achieving the reduction targets in:- The consumption and discharge of drinking water in plants, offices and the warehouse.

- Hazardous waste generation.

- Electricity consumption of the warehouse.

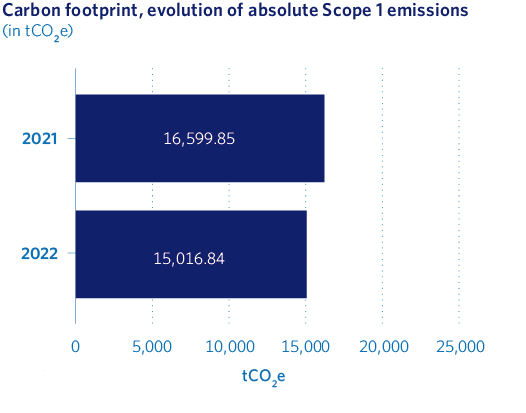

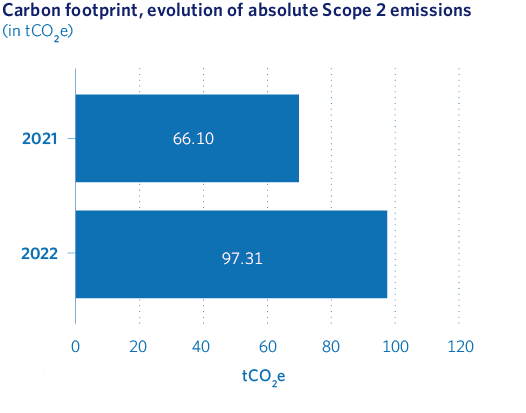

- A 3% reduction in scope 1 and scope 2 greenhouse gas emissions in 2022 with respect to 2021.

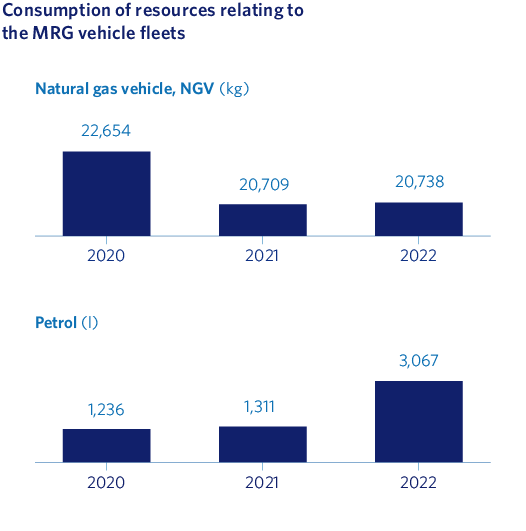

Analysis of the absolute emissions data for both years shows that we have managed to reduce scope 1 emissions by 9.5%, whereas scope 2 emissions have increased by 47.2%, so only 50% of this target has been met.

8.1.2 Dialogue with stakeholders

Various environment-related communication actions have been carried out with our stakeholders in 2022 (see the graph on the previous page).

8.1.3 Identification, evaluation and follow-up of environmental aspects

MRG has established a methodology for the identification and evaluation of environmental aspects associated with processes, activities, services, work centres and the vehicle fleet aimed at determining those that have, or may have, significant impacts on the environment and establish operational control over them, in its internal regulations.

This year we have reviewed said methodology, including the environmental aspects associated with the Alcorcón warehouse.

In addition, we have a control panel of environmental indicators, the results of which serve as feedback for the identification and evaluation of environmental aspects, as well as to establish priorities as regards management of the environmental risks of our activities.

The information in the following sections can be provided as a result of monitoring the environmental aspects related to our activities.

8.2 Consumption of resources

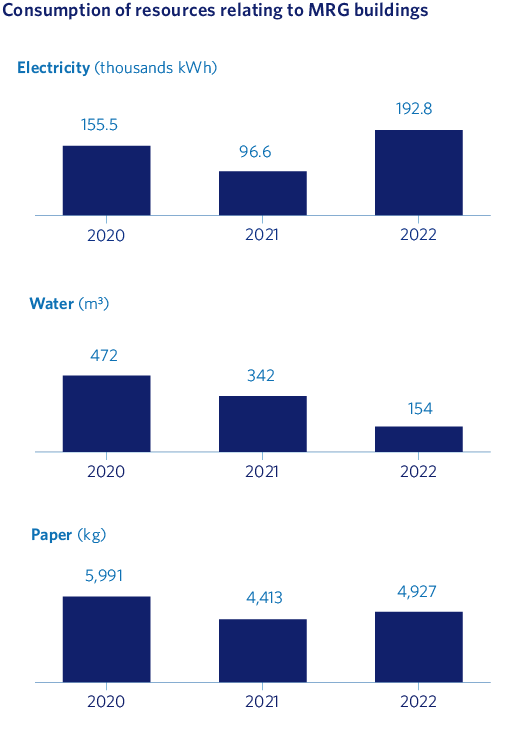

As we will see below, during 2022, some results regarding the consumption of resources are worse than expected, compared to the same period of the previous year.

Buildings (offices + Alcorcón warehouse)

The trend in the consumption of resources in our Pozuelo de Alarcón Offices is clearly downwards as a result of the measures adopted as part of the company’s strategy, including the promotion of remote working and the opening of a new work centre for the operators (warehouse), who are the personnel who most need these resources.

However, as can be seen in the figures, there is a significant increase in electricity compared to the previous year, mainly due to the fact that, as of 2022, consumption by the Alcorcón warehouse is included. In addition, the power supply in 2022 to the offices is only electrical as the changing rooms (the only source of natural gas consumption in the building) have been removed.

As regards paper consumption, as of 2020, the following data collection is taken into account: the sheets printed in the photocopiers in our offices and the paper used for envelopes (envelope+paper) for the management of several of our activities.

The increase in paper consumption is mainly due to the increase in the volume of periodic inspections this year compared to the previous one (increase from approximately 180,000 to 210,000 inspections) and the Dark Gas fraud-detection project. Letters have been sent on a weekly basis advising of boiler checks. Approximately 1500 have been sent per week since May.

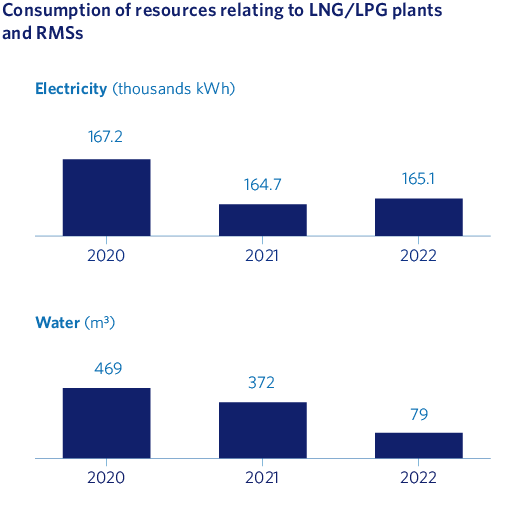

Plants and Regulation and Metering Stations (RMSs)

There has been a marked decrease in water consumption at our plants in 2022.

In addition, with regard to the products and materials consumed in said installations:

- In general, the main materials consumed in a satellite LNG plant are: THT, for the odourisation of natural gas, diesel in the tank for the generator set, and herbicides (occasionally).

- The main materials consumed in a satellite LPG plant are: oil for the decanter, in those installations equipped with a boiler, and herbicides (occasionally). These substances are used during maintenance and and are transported by the work team; they are not stored at the installations.

- The only materials consumed in an RMS are lubricating oils/greases, for equipment maintenance, as well as herbicides used in periodic campaigns.

Vehicle fleet

As can be seen, the consumption of natural gas by vehicles remains essentially the same as for the previous year, with a significant increase in petrol consumption. It should be noted that this does not include consumption of the vehicles for sales personnel nor those of the private vehicles of employees used by the company occasionally.

It should also be noted that, during the months of December 2021 to March 2022, a diesel SUV was hired for use as a reserve in special occasions or emergencies caused by adverse conditions. The consumption thereof is not considered as it is practically insignificant (48.56 litres).

8.3 Atmospheric Emissions: measurement and reduction commitment

Generally speaking, and with regard to the consumption seen above, we can see the evolution of direct and indirect atmospheric emissions associated with our buildings and our fleet of vehicles.

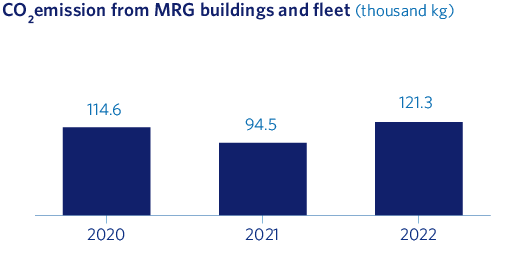

8.3.1 Methane Emissions

The atmospheric emissions of the natural gas distribution network (scope 1 and 3) are estimated annually as per a specific procedure. The new methodology for estimating fugitive methane emissions from the gas distribution network, established during 2021, is events-based, which allows improvement methods that significantly contribute to reducing methane emissions to be designed and applied.

During this year, and as discussed above, we have made progress in perfecting said methodology, separating the scope 1 and scope 3 emissions.

These scopes include:

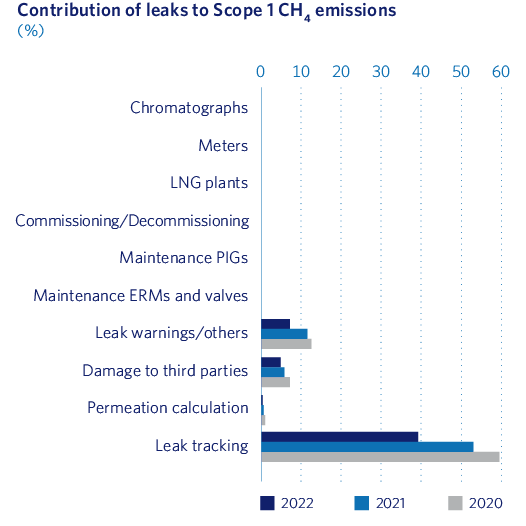

Scope 1: Leak tracking, Permeation calculation, Third-party damage, Leak warnings/others, Maintenance, Commissioning/Decommissioning, LNG plants, Meters and Chromatographs.

Scope 3: Leaks at receiving installations.

With regard to the number of leaks, in recent years it falls within the range 96–97% corresponding to receiving installations (Scope 3) 3–4% for networks and connections (Scope 1).

In light of the above information, we can see that the contribution of these leaks to methane emissions presents an asymmetric trait with respect to the results that we can see in the figure for the results of the two scopes. Leaks in networks and connections are being attributed a very significant contribution, especially those identified during tracking (in terms of methane emissions), compared to the rest.

The reason for this is that the methodology considers that the time that a tracking leak remains active is 8760 hours (one year) while the time that an emergency leak remains active is 4 hours, and the fact that the time that a leak in a receiving facility remains active is also 8760 hours (one year). For this reason, we believe that it is essential to continue to discuss those parameters of this methodology that need to be refined in Sedigas so that the results better reflect reality.

8.3.2 Our carbon footprint: measurement and verification

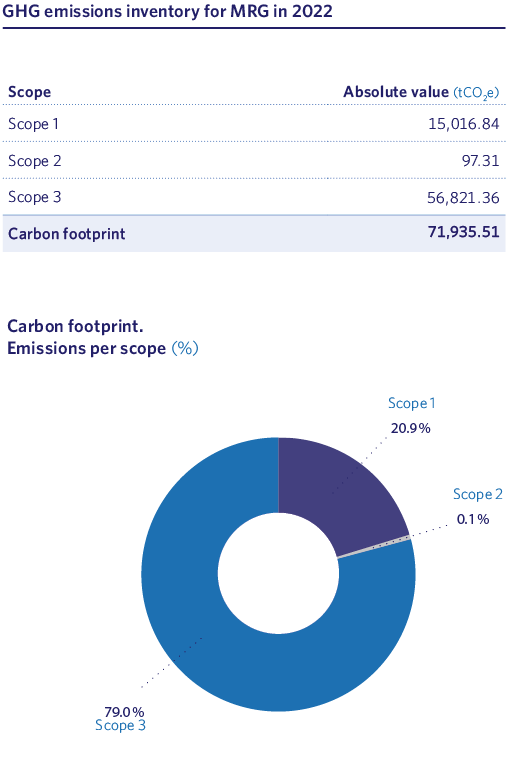

MRG has a tool for calculating the carbon footprint for the activities associated with the company, including direct emissions of Greenhouse Gases (GHG) (Scope 1), indirect GHG emissions from the generation of the electricity purchased and consumed (Scope 2), as well as indirect emissions produced in the value chain (Scope 3).

Although the quantification of direct GHG emissions as a result of our activity has been carried out for some time, two years ago the decision was made to address the verification of the GHG emissions inventory that constitutes our carbon footprint, in accordance with standard UNE-EN ISO 14064-1:2019 in order to provide it with official validity.

The scope and limits applied to the calculation of the carbon footprint are as follows:

- Head offices at C/ Virgilio, nº 2 B – Edif. 1. 28223 Pozuelo de Alarcón, Madrid (Spain) and the warehouse located at calle Valdemorillo, 60, 28925 Alcorcón, Madrid (Spain).

- Natural gas and LPG distribution network in the Community of Madrid.

- LNG and LPG plants belonging to the distribution network.

- Fleet vehicles.

In the 2022 period there have been no changes in the limits of the report with respect to the preceding period.

In order to compare emissions and evaluate the performance achieved, the sum of the results of the carbon footprint for two consecutive years (2021–2022) has been established as the baseline year.

This selection is due to the fact that network and connection monitoring activities are completed biennially for the entire network, therefore the emissions associated with this activity will not be complete until the entire network has been inspected.

Consequently, the analysis of the evolution of the complete carbon footprint with respect to the baseline year will be carried out every two years, starting in the period 2023–2024, so that comparable results are obtained with the 2021–2022 baseline year.

Finally, it should be noted that, at the end of 2022, and with the data obtained in the calculation, we carried out the second registration of the carbon footprint in the Spanish Office for Climate Change (OECC), obtaining the CALCULATION seal for 2021, which already includes Scope 3 and informing of the Reduction Plan. Out intention is to continue along these lines in coming years.

8.3.3 Commitment to emissions reduction and energy efficiency

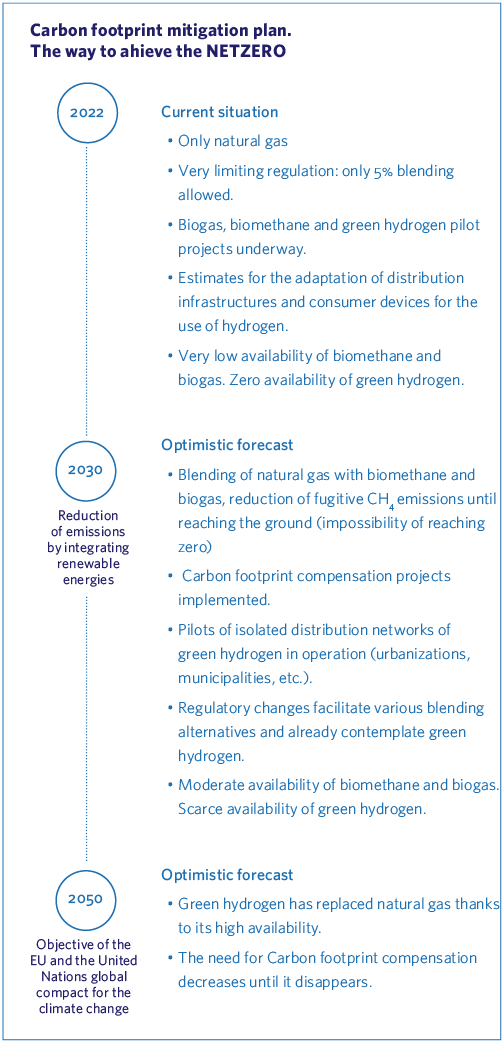

Madrileña Red de Gas is fully aware of the importance that climate change represents for companies and humanity in general. As such, we have set ourselves the challenge of meeting energy demand in an increasingly cleaner, safer and more reliable way, for which we must develop proactive actions, identifying initiatives that allow us to control the risks to which we are exposed in order to meet the requirements and expectations of our stakeholders.

Oportunity forescast

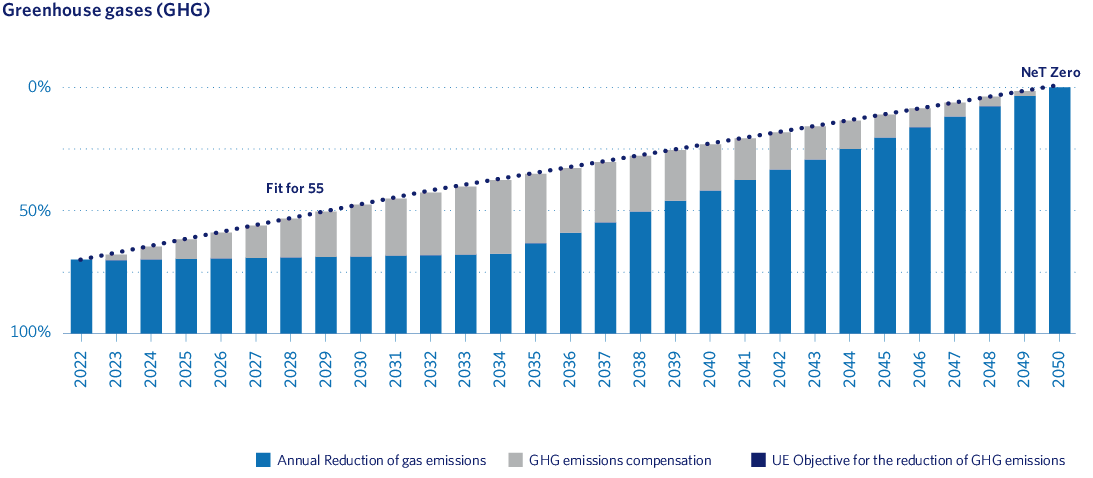

Annual carbon footprint compensations aligned with the projection of the EU objectives of “fit for 55”and up to “Net Zero”; and WITH REPLANCEMENT of natural gas by green hydrogen from 2035

In this way, as part of the fight against climate change, at MRG we are committed to reducing polluting gases that have a negative impact on air quality, ecosystems and health, especially fugitive CH4 emissions from the distribution network and CO2 and NOx emissions, establishing measures to reduce our carbon footprint (scope 1, 2 and 3) and promoting projects and investments aimed at promoting energy efficiency, and infrastructures and sustainable mobility (our own and those of the community in which we operate).

In light of this commitment, a proposal for a carbon footprint reduction/compensation plan, aligned with the objectives of “Fit for 55” for 2030 and “Net zero” for the year 2050, is being prepared.

In addition to the above, at the end of 2022, and in light of our commitment to reduce methane emissions, we was decided to establish an evaluation route and considered it appropriate to voluntarily adhere to the OGMP 2.0 program (Oil & Gas Methane Partnership), an initiative promoted by the United Nations Environment Program (UNEP), and which is part of the European Commission’s Strategy to reduce methane emissions, in 2023.

Moreover, with regard to measures carried out in terms of energy efficiency, it should be noted that the ventilation installation has been improved, as has the air purifiers installation in our offices in Pozuelo de Alarcón. These measures were carried out in response to the audit carried out during 2019 in relation to indoor air quality, the result of which was unfavourable in terms of CO2 concentration in work spaces.

The actions undertaken to improve ventilation levels in the offices include the following:

- Installation of new ventilation equipment with energy recovery from the extracted air, which complements the existing equipment, to achieve adequate ventilation levels. CO2 levels in the environment are controlled using concentration probes.

- Installation of duct networks to supply outside air and extraction to the offices from the new recovery equipment, to the diffusers and grilles.

- Power supply to recoverers and support resistors, from electrical panels existing on that floor, including magneto-thermal protection of said lines.

- Increase in the section of exterior grilles for the intake and discharge of outside air in roof towers and relocation of existing ducts in small shafts.

- Dismantling and subsequent assembly of the false ceiling plates and profiles where required to install the new equipment and duct networks.

In search of better environmental practices

In addition to the above, in 2022, and with the aim of strengthening our environmental performance, we made the decision to start investigating possible actions that could be adopted, as well as environmental experiences and issues that may be of interest to MRG. For this reason, a search for good practices and benchmarking was initiated, based on the public information available from leading companies worldwide, the United Nations, government institutions and environmentalists, as well as different public and private organizations specialising in efficient environmental management. which will allow the different strategies at Madrileña Red de Gas to be aligned with its institutional commitment, as well as its management and strategic objectives.

For this investigation we made some assumptions that could serve to prioritise and choose possible alternatives, including:

- Actions reported and recognised in Spain.

- Location and/or area of influence.

- Lines of interest for MRG, especially alternatives falling within the scope of:

- Water and diversity.

- Energy and decarbonisation.

- Circular economy.

- Mobility.

- Financing and costs.

- National and international recognition.

- Environmental accountability.

- Relationship with Sustainable Development Goals.

- Legal requirements, which allow the use of “green” alternatives for service provision.

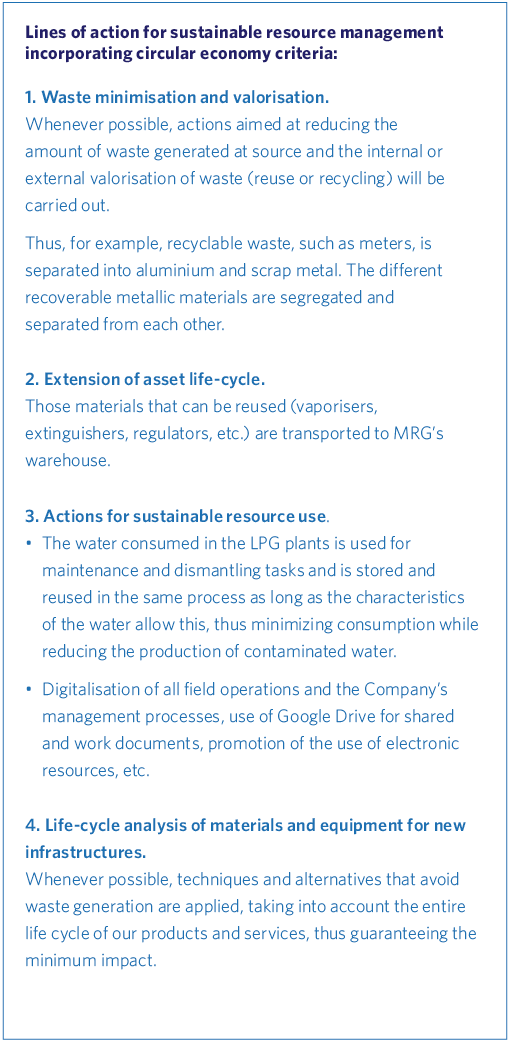

8.4 Circular Economy

One of the challenges that MRG has set itself is to make progress in the sustainable management of resources by incorporating circular economy criteria into the framework of four lines of action:

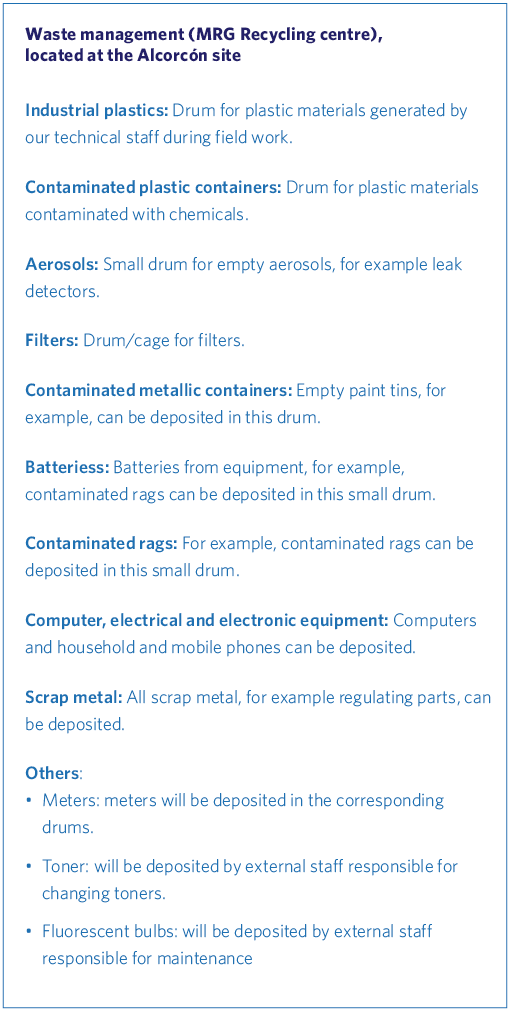

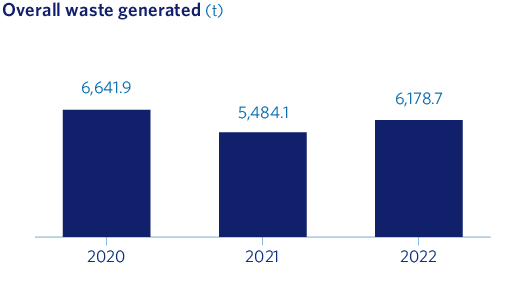

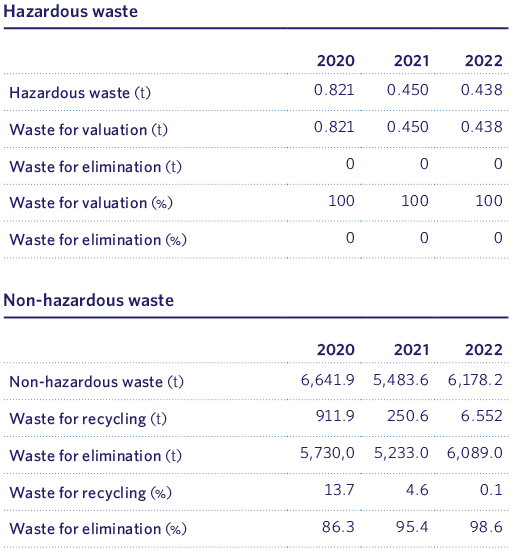

8.4.1 Waste

Madrileña Red de Gas has specific procedures for the management of its waste in which the criteria for waste generated at work centres, logistics centres and industrial installations (Regulation and Metering Stations (RMSs), Liquefied Natural Gas (LNG) plants and Liquefied Petroleum Gas (LPG) plants) are established.

The main waste that can be generated in a Regulation and Metering Station (RMS), in an LNG plant or in an LPG plant arises due to maintenance operations:

- Lubricating oils/greases

- Rags/absorbents

- Occasionally, batteries, fluorescent bulbs, etc.

- Batteries

- Used filters

Such waste is generated occasionally and is removed by the maintenance team when generated.

In addition, during dismantling, and under supervision of the Project Management, the waste management plans of the contractor companies are thoroughly reviewed and all the documentation related to waste management is compiled.

In this sense, during 2022, 14 LPG plants have been dismantled in coordination with the Town Halls of different municipalities of the Community of Madrid, carrying out the emptying, burning-off, inerting and removing a total of 19 tanks. To that end, it has been necessary to carry out more than 15 journeys in order to transfer the emptied gas to other Madrileña Red de Gas plants, thereby avoiding emissions into the atmosphere, and to the transport the waste obtained during said dismantling to the treatment plants authorized by the Community of Madrid, respecting the commitment of Madrileña Red de Gas to the environment, and all without interfering in the usual dynamics of customers and neighbours.

In addition, at the new work centre located in Alcorcón, we have created a recycling centre where both solid and urban waste is processed, via the service designated by the City Council, along with hazardous waste. We have also requested the NIMA code (Environmental Identification Number) that unequivocally identifies each waste-producing or -management activity from the Community of Madrid, thus allowing us to register the centre as a small waste producer and be able to collect it.

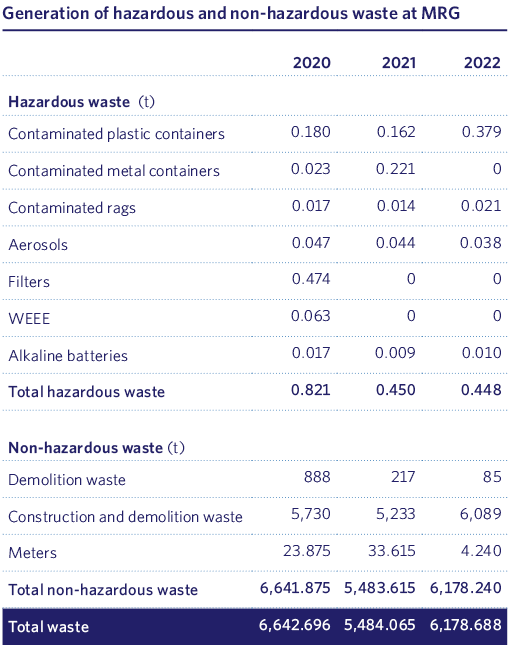

As can be seen from the table, there has been an increase in the generation of plastic containers and contaminated rags. However, demolition waste has decreased considerably because, as mentioned previously, this year 14 LPG plants have been dismantled, 23 fewer than last year.

In the case of filters and IT devices, the result is the same as the previous year, in other words none of this type of waste has been generated.

The quantity of hazardous waste remains similar to that for the previous year (only 2 kilograms more have been generated), although the amount of non-hazardous waste has increased due to the construction and demolition waste (CDW) generated.

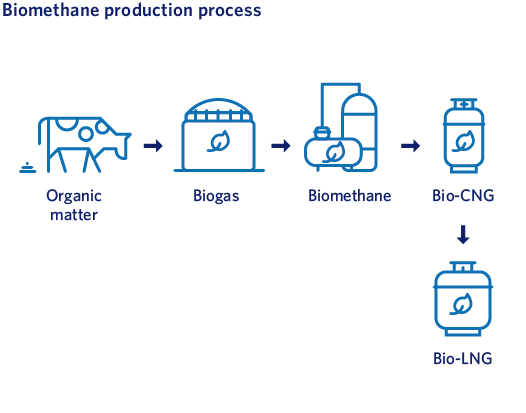

8.4.2 Biomethane

Biogas is a “gas, formed mainly by methane (CH4) and carbon dioxide (CO2), obtained from the anaerobic digestion of biomass”, which is a biological process that occurs in

the absence of oxygen in which, as a result of the action of various groups of bacteria, organic matter decomposes to give two main products: biogas and digestate.

Biogas is purified in a later stage known as upgrading, in which impurities are removed and methane is concentrated, thus resulting in a molecule identical to fossil natural gas, except for its renewable origin.

The draft Biogas Roadmap establishes a biogas production target of 1.41 TWh per year in 2030. Europe-wide, it is expected that 10% of the total consumption of natural gas in the EU will come from biogas in that year.

There are currently four biomethane projects in the MRG network:

- Guadalix de la Sierra

The project aims to develop a plant for the recovery of livestock and agro-industrial waste in Guadalix de la Sierra. In this case, Madrileña Red de Gas is leading the development of a project that aims to provide a complete solution to the more than 20,000 tonnes of bovine slurry generated in the municipality per year.The project is being studied from an environmental, energy and agronomic point of view, and the town council is continuing to work on the development of an energy community that accommodates the project.

Two uses are proposed for the biogas:- Direct use in a cogeneration plant to produce electricity. This alternative opens the door to the creation of an energy community in the municipality, with the aim of supplying residents with renewable electricity.

- The biogas produced will be purified by way of an upgrading process and then compressed to produce biomethane. This can be used as natural gas for vehicles or be injected into the natural gas network.

- Cubas de la Sagra

A project for generating biomethane from food waste, with a treatment objective of 70,000 tonnes per year. The plant will be designed for a production of 500 m3/h of biomethane.

MRG has designed a Reverse Flow in our distribution network, which will allow gas to be injected from the medium-pressure network into the high-pressure network, to be able to absorb the production of the future plant. - Landfill site with biogas production

In one of the municipalities where we distribute natural gas, there is a closed landfill site that currently produces biogas.

It is in this phase, when the landfill site has already been closed (closed and sealed), when biogas recovery takes place. This is a by-product that is generated during the anaerobic decomposition process of organic waste in the landfill.To recover the biogas from the landfill, a gas collection system consisting of pipelines and wells, designed to capture the gas produced, is installed. After being captured, the biogas is transported to a treatment plant where pollutants are removed and it is converted into biomethane, which can be used to produce electricity,be injected into the grid, or used as fuel for vehicles.

In the case of this landfill, MRG received a request from the company that manages it to be able to inject that biomethane into the natural gas network. After studying the consumption of that zone, it was confirmed that the network will be able to absorb the amount of biomethane that is produced. As such, MRG will manage the injection point and the new distribution infrastructure that will be necessary to connect the landfill to the natural gas network.

- Biogas production plant in the north of Madrid

As in the case of the Cubas de la Sagra plant, there is another biomethane plant construction project in one of the municipalities in our network. The developer requested a study of the capacity of our network to absorb the expected production.

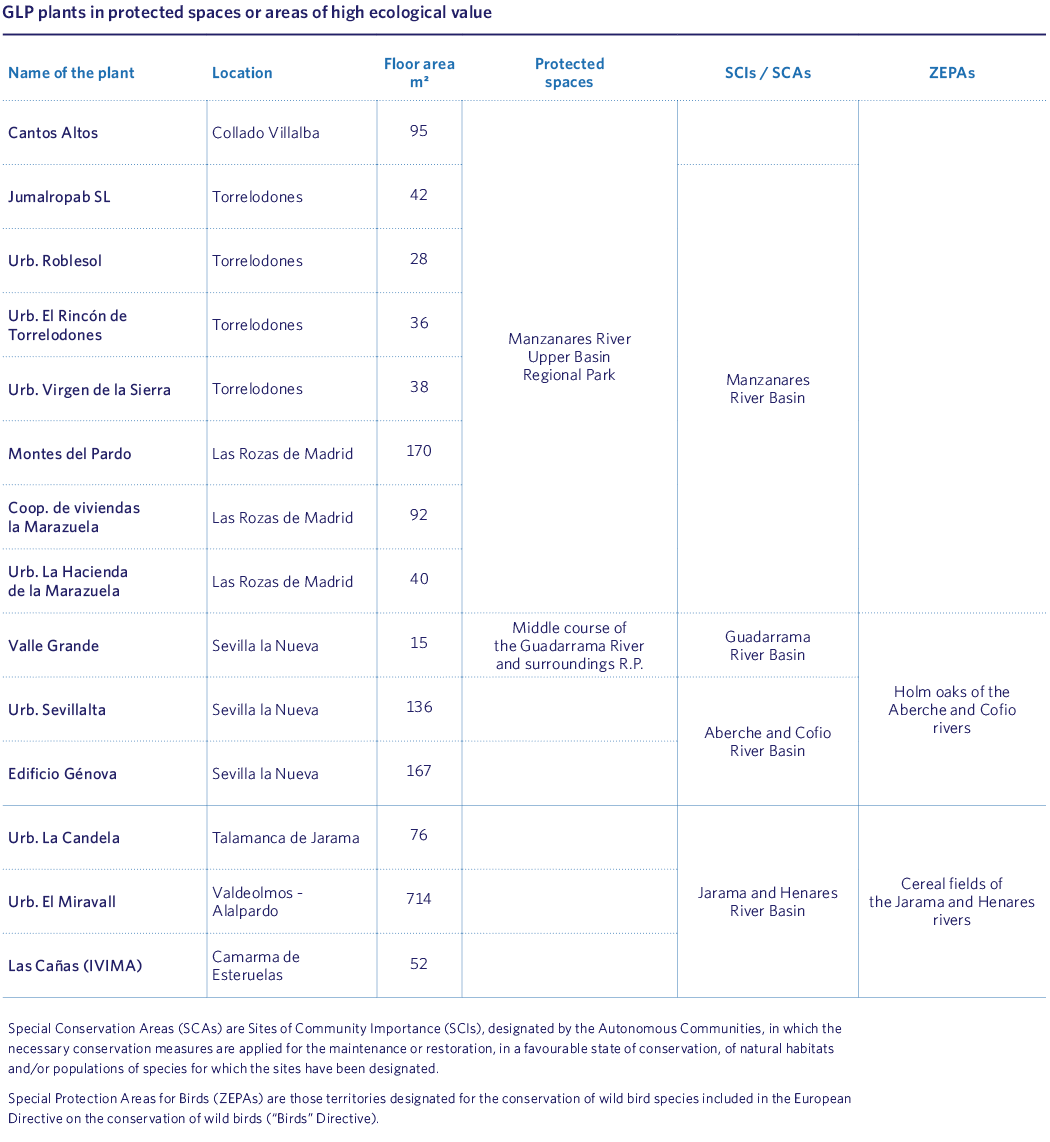

8.5 Biodiversity

In fulfilment of our commitment to guarantee the supply of gas in all those regions of the Community of Madrid where it is necessary, a small number of our installations are located in protected areas or areas of high ecological value.

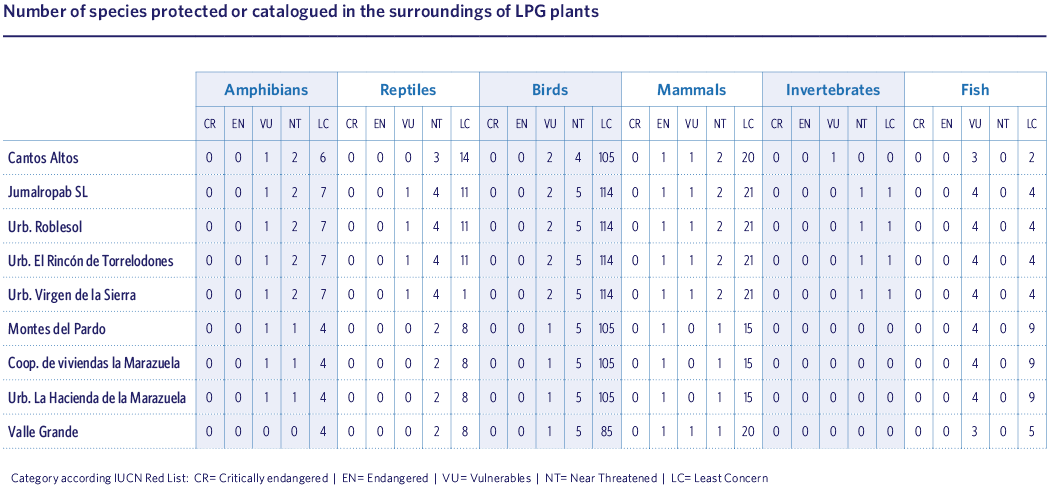

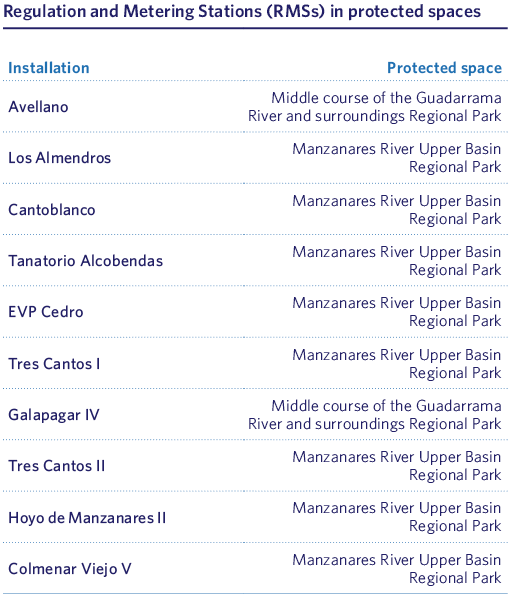

At the end of 2022, Madrileña Red de Gas had 128 LPG plants (after the transfer of 20 of them to Aliara) and 5 LNG plants. Of these, only 14 LPG plants are located in protected areas or areas of high ecological value (no LNG plants). As regards our 206 Regulation and Metering Stations (RMSs), 10 are located in protected areas. None of the 14 plants dismantled in 2022 were located in a protected area or special protection area.

As can be seen, there is no species in critical danger (CR). However, there is an endangered mammal (EN) species, namely the common or European rabbit.

8.5.1 Our environmental responsibility

With regard to environmental damage associated with the installations, the activities carried out by MRG are included in Annex III of the Environmental Responsibility Law (Law 26/2007) and, therefore, we are subject to the following obligations:

- Notification of the existence of environmental damage or the imminent threat of such damage to the competent authority.

- Adoption of:

- Preventive measures

- Avoidance measures

- Reparation measures

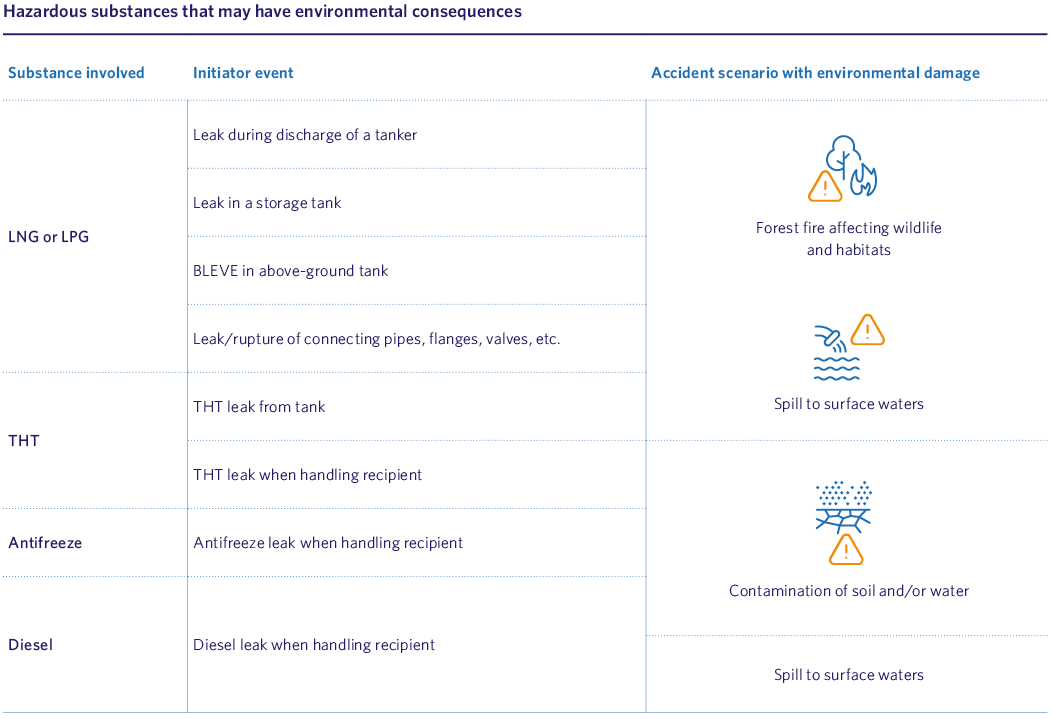

At our installations, the following substances have been identified as sources of danger for the different natural resources present in the environment, and therefore for biodiversity:

- LNG (present in LNG plants and the distribution network)

- Commercial propane (LPG; present in LPG plants and in the distribution network for those plants supplying the municipal network)

- THT (present in LNG plants)

- Antifreeze (present in LNG and LPG plants)

- Diesel (present in LNG plants)

Given their physicochemical characteristics, these substances are associated with a series of inherent hazards that may have environmental consequences.

In the event of a leak, LNG turns into a gas in contact with the atmosphere. In the event of a leak, LPG also turns into a gas in contact with the atmosphere, although it is denser than air and therefore accumulates close to the ground. In both cases, no liquid spill that could cause contamination occurs.

As in the case of LNG, LPG is a hazardous substance as it is explosive and inflammable, therefore one of the greatest hazards is the possibility of causing an explosion or fire.

THT is an inflammable liquid that may also cause contamination of the soil or water and is also harmful for aquatic organisms.

With regard to possible spills, the five LNG plants have a dyke for containing the spilled product, thus meaning that any leak of LNG in liquid state or THT is always contained in the dyke.

Given this information, and taking into account that reparation measures are only adopted once the specific damage has occurred, proposing specific reparation measures in each case, the measures available at MRG’s facilities and activities to deal with these risks are included in the Risk Management section of this report.

Prevention of forest fires

As noted above, the greatest environmental damage that our activity can cause to the natural environment and, therefore, to biodiversity, are forest fires.

Generally speaking, with regard to forest fires, all installations must comply with the provisions of Decree 59/2017, which approves the Special Emergency Civil Protection Plan for Forest Fires in the Community of Madrid (INFOMA).

According to that Decree, special attention must be paid to the municipalities considered as areas at high risk for forest fires. In the Autonomous Community of Madrid, the following must have a Self-Protection Plan: National Parks, Rural Parks and Natural Parks, as well as other protected natural areas that are within the High Fire-Risk Zones (ZAR).

In addition, said Decree establishes a series of preventive measures applicable to installations adjacent to forest land, such as generally prohibited uses and activities.

In the case of installations adjacent to forest land, less than four hundred meters from forest land, or located in forest land, “It is the responsibility of the municipalities to determine, through a delimitation plan, the housing estates, buildings and facilities affected (…)” for the obligations specified in Annex 6 of INFOMA, such as:

- Drafting a self-protection plan against forest fires

- Ensuring the existence of a perimeter protection strip thirty meters wide, free from dry vegetation and with the tree mass cleared.

- Keeping unbuilt plots free from dry vegetation and with the tree mass cleared.

- Having a network of approved fire hydrants that meets the characteristics established by the Technical Building Code.

- Maintaining private roads, both internal and access roads, free from dry vegetation, as well as verges.

Finally, it should be mentioned that, during this period, there have been no accidents with environmental effects that were associated with fines or civil liability during 2022.